BSA B175 Bantam. . . . yet

again

Yes - I've only gone and bought another one

Having sold my

B175, then also selling my

D14/4S, it left a bit of a Bantam shaped hole in the garage.

I know I sold the other two 'cos I didn't use 'em enough, but I

did rather miss the few occasions when I needed a "Bantam fix",

and besides, I'd also miss the folks from the owners club on the

national rally and other events. Anyway, whilst

looking on the forum of the Bantam Owners Club I noticed a B175

was up for sale. OK, so it wasn't a running machine and it

was over 200 miles away - but what does that matter ? I

don't mind travelling, in fact I quite enjoy it, and I do get

pleasure from working on bikes as well as riding 'em. If

only I'd have known . . . looks like I will be getting a lot of

"pleasure" with this one - still, time spent in the garage is

always time well spent. So on Tuesday the 5th of May, I

hitched the trailer to the Bongo and set off for Kent - and by

three o'clock in the afternoon I was back home with something

Bantam shaped.

Right,

the first thing was to take a quick look around

and see what obviously needed doing. First

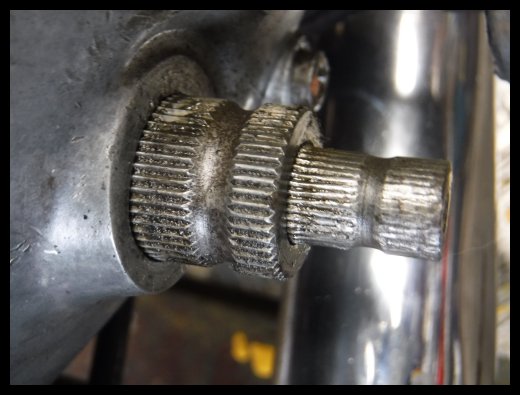

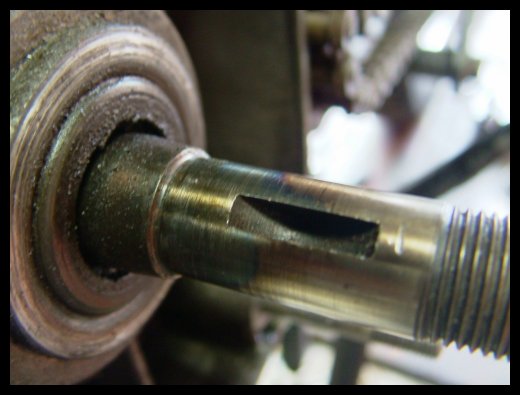

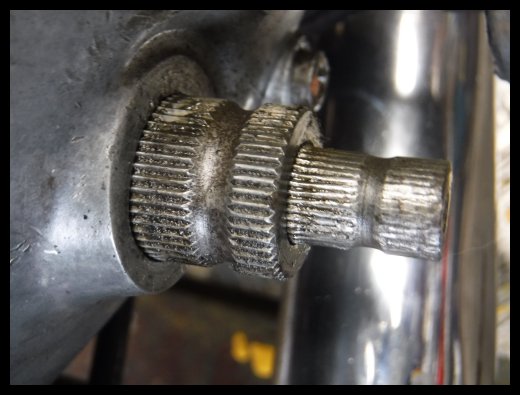

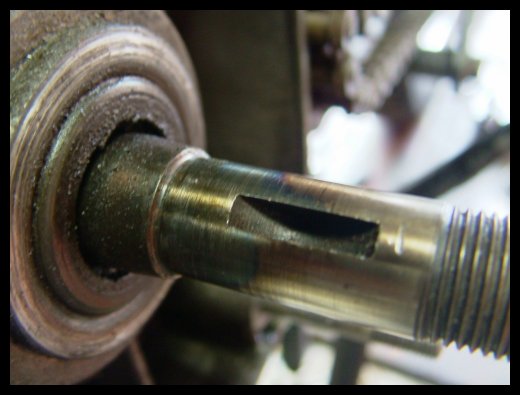

thing was the gear lever spinning on the shaft.

Oh dear, those splines have seen better days.

Luckily I have a decent four speed gear change

shaft in the garage.

Next things to immediately jump out was the

chrome ( or lack of ) on the headlight rim and the perished footrest rubbers.

Once again, an easy fix.

I did rig up my remote fuel tank and have a

quick couple of kicks when I got the bike home, but it showed no signs of

wanting to start and the kickstart kept jamming when trying to kick it.

That will be looked at later.

Right, first thing is, take a look and make

sure the carb is clean. Oh dear - the inside of this carb has not seen

daylight ( or petrol for that matter ) for quite a while. The bottom of

the float bowl was full of crap and there was what looked like a cover of some

description over the main jet. This cover turned out to be a fine gauze

which had such a build up of crud on it that it gave the appearance of being

solid. I'd never seen gauze on a main jet before. It was probably

put on in the hope that it would somehow act as an additional fuel filter . .

.but any restriction in the main jet will only cause the engine to run weak and

most probably seize. No wonder the bike wouldn't even attempt to run.

When I sold my D14 last year, I also sold my

spare B175 engine - and this engine was sat on an engine stand. Seeing as

I made the stand from bits and pieces from in the garage, I thought it would be

a good idea to build another one before I go much further. So a few bits

were cut, drilled and welded, and I now have something to hold the engine whilst

I work on it.

Now

that the engine is sitting happily on its stand ( can you sit on a stand ? ) it

was time to dig further. Next obvious thing was the up and down movement

of the crank shaft on the alternator side. Looks like a set of main

bearings will be needed - and if the mains have gone, you can bet the oil seals

have gone too. There was a bit of bluing on the main shaft, this could be

down to the alternator rotor spinning because the woodruff key which prevents it

from doing so was sat in the bottom of the casing. I took the head,

barrel and piston off next - it's a new +040 piston and the rebore has been done

by PJ Engineering, a company local to me. If PJ have done it, then that's

one thing I won't have to worry about - they are good at what they do. I

spun the crank via the con rod, and you could hear the rumble of the worn main

bearings. I also noticed a lot of clean oil coming round with the

flywheels, this also makes me think the oil seals are badly worn.

Let's see what delights await in the other side of the

engine. First thing I noticed was the worn primary chain - it was also an

endless chain, so both the clutch drum and the engine sprocket really need to

come off together. Now here's a little tip: When using a puller to remove

the engine sprocket, put the points cam back on or you will stand a very good

chance of breaking the end of the crank shaft - I know more than one person

who's ended up with a broken shaft. The clutch was next to be pulled

apart. The plates were well stuck together - it's been a long time since

this clutch disengaged. I used my home made clutch drum locking tool to

remove the clutch centre nut - easy enough to make, just an old friction plate,

a couple of nuts and bolts and length of steel strip. The kickstart ratchet

seemed ok - I'll have to find my spare quadrant and compare it with the one I

took from this engine. The leading tooth looks worn, but I'll leave

judgment until I compare the two.

Next job was splitting the crank cases.

This engine has been apart before because all but one of the fixing screws had

been replaced by Allen bolts. Luckily all of the bolts came out easily and

none of the threads seemed damaged. There was one bolt missing and one

original cross head fitted. I don't know what had been used as jointing

compound, a barrel of tar springs to mind. There was a load of the stuff.

It was in the gearbox and stuck in all the webs of the castings. Cleaning

that out will keep me entertained, or I might just get all the cases vapour

blasted. The gearbox seemed to change through all four gears easily

enough, and although some of the gears looked worn, I don't think they will need

replacing. Once again, I have a spare four speed box living in a biscuit

tin in the garage. I tend to keep it as a reference when looking at other

people's gearbox problems.

Time to play with fire, and get the crank

cases hot enough to make removing the bearings easy. As I thought earlier,

all the oil seals were badly worn, so they will be replaced along with the main

bearings and the gearbox output bearing. It makes sense to change it

whilst the engine is apart . . . along with the gear change return spring.

A new spring costs less than five quid, but it's an engine out job to fit one.

Right, that's enough for now. It's only taken a couple of days to get this

far. I'll press on with the rolling chassis whilst waiting for engine

parts.

A couple of little things today - first off was fitting a

side stand. The type that fits onto the front engine mounting bolts are

not very good. Being at the front of the bike means that there's a good

tendency for the front wheel to lift off the floor and the whole plot to come

crashing to the floor . . this is even more so if you have a carrier fitted and

attempt to load camping gear or such like. Fortunately those nice people

at Kawasaki make a very nice side stand for their ZZR600 - which just happens to

fit nicely on the pillion footrest mounting plates of a Bantam. The other

thing was the bike's log book arriving, not bad considering I only picked the

bike up a week ago today. Whilst working away I noticed something on the

rear tyre. Some lettering that someone in the past had tried to remove

with sandpaper or similar. I know the photograph isn't the best, but you

can make out the words "Remould Quality" Now I never knew they made

remoulds for bikes - cars yes - I used to have 'em on my Land Rover many years ago.

As far as I'm concerned, tyres and brakes are something that I always fit new.

You don't know if that tyre has been rammed up a gutter, or run flat for any

length of time.

Whilst waiting for bits, I carried on with

making the bike look generally nicer. First off was all the tinware that

was to be powder coated in whatever colour I fancy - there's a good chance it

may be purple. The rest of the bits will be gloss black. I tend to

make a numbered list of what goes to be coated, that way both you and the powder

coating company have a list of what's what.

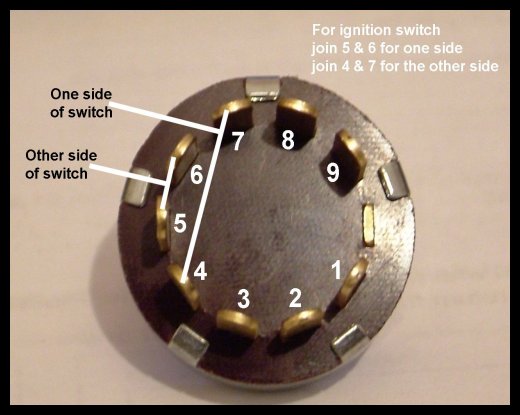

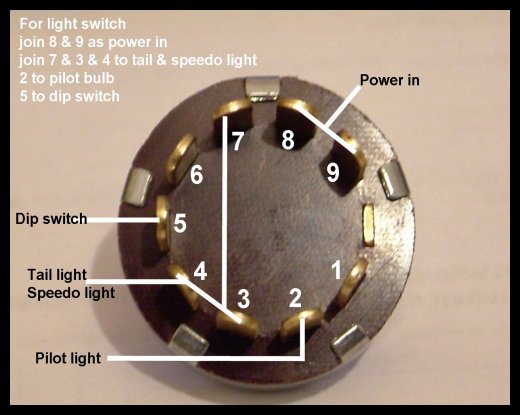

As with every other old bike I own,

this will be converted to 12 volts. This improves reliability

and give a greater choice when it comes to bulbs, plus most car

spares places sell 12 volt bulbs, but very few stock 6 volt

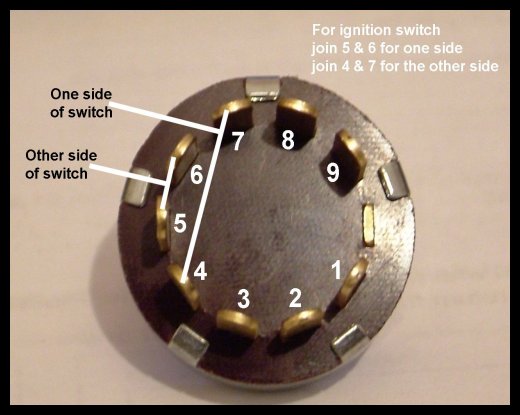

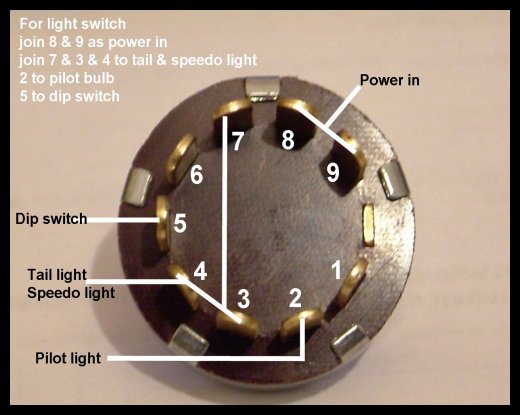

items. I tend to use a simple key switch for the ignition and a

simple toggle switch for the lights - doing away with the "pilot

light". . . . now a friend of mine wanted his bike converted to

12 volts but wanted to keep the standard switches in the

headlight shell. A few minutes messing around with my test

meter and a few wires with crocodile clips on the end solved

this problem. Just to prove I practice what I preach, I will keep the standard

headlight mounted switchgear - I will probably fit a "hidden"

key switch if I can find a suitable place to fit one - as you

know, there ain't a lot of spare room on a Bantam.

When I bought this bike I was told that

the kickstart sometimes locks and the bike has to be put into

gear and rocked in order to free it. I suspected the

leading tooth on the kickstart quadrant had worn - and as it

turned out, I was correct. Looking at the quadrant it

seems like it could be turned the other way round so the unworn

trailing tooth now becomes the leading tooth. I did ask

the question on the Bantam Club Forum, and "BantamBaz" gave me

the answer. "No - there is an offset on the casting"

Ah well, time to buy a new one - they ain't expensive.

Having sorted the kickstart quadrant

out, it was time to carry on with putting the engine to rights. By now my

new bearings and seals had arrived, so armed with my trusty blowlamp I set about

warming the cases up to make fitting the bearings easier. OK - I could

have bunged them in the oven for twenty minutes, but I like playing fire.

Now that the bearings and seals were fitted, I dropped the

crankshaft in and made sure all was well. ( famous last words ) I didn't fit the gearbox

internals - there's no point if you have to keep taking the two crankcase

halves apart to fit shims on the crank. . . . besides, I want to take a look at

the gearbox internals before refitting them.

Speaking of bearings - I next turned to the

wheels. The chrome on the rims is non existent and has been painted over.

The spokes are loose, and a few are bent . . . so I reckon there's a good chance

that the wheel bearings ain't much better. A useful tip in these days of

smart phones and digital cameras is to photograph the components in the order

they come off. This makes putting it all back together again a less

daunting task. "Did that spacer go behind or in front of the bearing ? "

Refer to the photograph and all becomes clear.

As you can see from the picture, one of the wheel

bearings had started to break up. Looking at the identification marks on

the bearings, I wouldn't be surprised if they were the original fitment.

Another useful little tip is - buy a pack of plastic freezer bags - then put

components which group together in a bag . . . and label it.

Remember when I dropped the crankshaft in to

make sure all was well ? Well it wasn't - the right hand flywheel

was running out of true by around.040" Once again I just happened to

have a spare crankshaft. I'll get the other one repaired at my leisure.

The cylinder head was treated to a bit of very mild sand blasting - it cleaned

up quite well, but there is a fair bit of pitting on some of the fins. The

combustion chamber is fine.

Does this mean the engine is done ?

Indeed it does. The only thing I could have changed were the clutch plates

- they still have a lot of meat left on them, but I don't know how well the

bonding will stand up. I dare say I'll find out when the time comes -

besides, changing clutch plates isn't exactly an all day job. The

gearbox seemed ok - nothing too badly worn, so that went back in with a new

return spring and a shaft with decent splines on it. Main bearings, oil

seals, primary chain, and kickstart quadrant are all new, as is the piston and

bore. I sat the engine outside in the sunshine, and showed it what it will

grow up into one day. The big egg and the little egg.

Now here's a thing. When it comes to

undoing the bearing retaining rings in the front and rear wheels, why do people

think a hammer and centre punch is the best way of undoing them ? Get

yourself an old spanner that's about one and a half inches wide and lash out on

a couple of 3mm ( one eighth for us old buggers ) roll pins - you can get a set

of assorted sizes for under a tenner, and they always come in useful. Now

take your retaining ring and file off the mess made by the centre punch wielding

butcher, then drill the holes right the way through. Using the retaining

ring as a "drilling jig", drill two holes of the correct diameter for your

roll pins in the spanner. Congratulations - you have now made a peg

spanner. No more hammering away at things that were never meant to be

hammered on. . . . and you can still use the spanner for its intended use

( at a push ). This will come in useful later on when I get the rebuilt

wheels back.

Whilst other bits are

away being sorted out, it's time to turn to the carburettor.

Ultrasonic cleaning is good, but an ultrasonic cleaner large

enough for a carburettor body is a tad expensive. Time for

another little useful tip. Get an old saucepan, fill it

with water, then add washing powder . . . and give the

carb a good boiling. The agitation of the boiling along

with the cleaning of the washing powder will shift any nasty

things which are lurking within the carburettor drillings.

A blow through with carb cleaner afterwards, just to make sure

everything is clear, and all being well you should have a carb

which does what it's supposed to. With the ethanol in

today's fuel, it's a wise move to fit a Viton tipped needle, and

possibly the new "stay up" float. Once again, these items

can be fitted in fifteen minutes at a later date, should the

need arise.

Next on the list - front forks. Oh dear, those

stanchions have seen better days. Being a

B175, they have "heavyweight" forks. I

suppose they are heavier than the forks on the

earlier models, but the forks on the Sport and

Bushman are even heavier - in fact they are the

same forks as fitted to the Starfire.

Anyway - B175 fork stanchions - virtually every

dealer is showing them for sale, but none of

them have them in stock. This calls for

plan "B". Get the original ones

refurbished. Brook Suspension seem to have

a good reputation, so that's where I've sent

them . . . time will tell. Speaking of

refurbishment, the powder coating has now come

back, and I must admit, I'm more than pleased

with the result. OK, it's a colour that

can never be matched - it's a "made up" colour.

Silver was done first, then a fine coat of the

secondary colour applied, this gives an almost

metallic finish.

Now for folks thinking that "doing up" a

Bantam is cheap - it costs as much to build a

wheel for a Bantam as it does for a Vincent.

OK, other bits may be cheaper, but so far the

bill for this bike is up over £1000, and I ain't

factored in the rebuild of the wheels and a new

exhaust system yet. Fortunately the rewire

won't cost me much - I still have most of what I

need from the last couple of bikes I rewired.

I can't do much with the frame

until the wheels are fitted -

and I can't fit the wheels until

the forks are fitted - do you

see where I'm going with this ?

One thing I can fit is the

swingarm. The bushes don't

show any signs of wear, and the

spindle looks good. I have

a feeling the bushes and spindle

are new items, mainly because

the bolts which hold the spindle

in place are cycle thread with a

pitch of 26 threads per inch.

The correct spindle for a B175

should be a much coarser thread.

You can fit the spindle with a

bit of persuasion with a large

hammer, but a press makes things

a lot easier.

Having got the swingarm back in, the next item was the carburettor.

By now my new 180 main jet had

arrived, so it was just a case

of putting all the bits back

where they came from.

Time to take another look at the

electrics. It seems the

rotor is an accident waiting to

happen. The centre has

come loose, and if those bits

start flying apart when the

engine is running, then you

could be looking at a big repair

bill. . . so this "electric

grenade" has to go. I do

not have a spare rotor, and it

seems there are none for sale,

so that leaves three options: 1

- try and make an adapter sleeve

so I can fit a conventional ¾

inch rotor. 2 - try and obtain a

new rotor. 3 - change the entire

system for something more

modern.

Whenever I've done work for other people, usually on the

flywheel magneto Bantams, I've

always advised them to fit

Electrex World systems.

Other systems are available, but

I've never had any problems with

Electrex World units, and when I

needed advice, I found them to

be more than helpful - even to

the point of trying different

ignition boxes on a bike I

trailered down to them.

So, after taking my own advice,

I've ordered a new charging /

ignition system.

This new system means that the original switch gear in the

headlight is no longer suitable

( OK, so the light switch is )

so I've reverted back to that

old faithful - the keyed

ignition switch and the toggle

light switch.

I've also made a start on fitting indicators to the rear using a stainless steel bracket

which attaches behind the number

plate. This means that

should you wish to remove the

indicators and revert the bike

back to original, then it's

simply a matter of undoing a

couple of bolts. I also

changed the rear light for something that actually fits the number plate

mounting bracket.

The petrol tap I normally use is one for an Indian Enfield - I've got one on my

B31, and on my Guzzi, and it works well. Seeing as I had both the

Bantam tank and the B31 tank on the bench following re-sealing with POR15, I

grabbed the tap I'd used on the B31 tank and made sure there was no sealant left

in the threads. I then fitted the petrol tap back in place. Seeing

as I had the tap in my hand, I drilled out the Bantam tank and tapped the hole

in readiness for the new petrol tap. Oh dear, that seems a bit loose.

It turned out that my new petrol tap had a ¼ inch BSP thread,

but the other tap ( in the B31 tank ) is a 3/8 BSP. Time for plan "B".

I've ordered a brass bush with a 3/8 BSP male thread and a 10mm hole in the

centre - I've also ordered a ¼ inch BSP tap and a suitable tapping drill.

Hopefully it will all work out in the end. It wouldn't be as much fun if

you didn't make the odd cock up now and again ( or again, and again, and again,

in my case )

The Electrex World kit has now arrived, so it was off with the

old, and on with the new. It's a simple system to fit, almost as easy as

fitting the standard rotor and stator. With the piston at top dead centre,

you just line up the two blue timing marks and it should be good to go.

It might seem an expensive bit of kit, but if you price up a new stator and

rotor, then add the cost of a regulator / rectifier, and add electronic ignition

on top of that, you'll find there's not a lot of difference, price-wise.

Having fitted the new rotor and stator, I couldn't really test it without the

engine being in the frame, and that isn't going to happen just yet. I have

no wheels and no fork stanchions, so until they arrive, there's not much I can

do.

Still awaiting forks and wheels, so let's get on with a few more

bits. First off was fitting the steering head, complete with 48 new ball

bearings. Whilst I had the frame up on the bench, I "dry fitted" the inner

panels for the toolbox and air filter, along with the battery carrier - which

has been modified to take the different shape of the new 12 volt battery.

Next up was fitting the rear mudguard, but not until I had fitted the rear light

bracket and the number plate. The whole mudguard / number plate / rear

light assembly was then wired up, terminating in a six way plug connector.

This makes life much easier when it comes to wiring the rest of the bike up,

plus it makes life simpler should you ever need to take the back end off again

for any reason. Now that the mudguard is in place, I next fitted the

carrier. A stainless steel item which actually fitted the bike without any

modification, so well done "Classic Bike Racks".

Remember that petrol tank that I messed up earlier on ? Well

after a bit of faffing about I finally got the hole down to the correct size for

the petrol tap. A quick test with a pint or so of petrol proved that there

were no leaks, so it was time to try the tank on the frame. Because of the

lug for the steering lock, the tank has to be spaced out to the right otherwise

the lug will hit the seam. This isn't a problem with the earlier tanks,

but the "jelly mould" tanks have the seam in a different place. After a

bit of fettling, I got the tank to sit on the frame with the bottom yoke of the

steering head missing the seams on both left hand and right hand full lock.

So that can now be put on one side whilst I carry on with the rest of the bike.

Whilst waiting for the front end to come back, I carried on with

wiring the rest of the bike up. To make life easier, I sat the frame on a

little trolley ( it used to be used for wheeling bread baskets about ) which

means I can at least move the thing out of the way when I need to work on other

bikes. The other thing about having the frame on the trolley meant I could bolt

the engine in place. With the engine in the frame, I rigged up my remote

fuel tank and started the engine. It runs with no rattles or bangs, and

the charging system works . . so that's a big step in the right direction.

The wheels have now come come back, so the first job was to get some new

tyres and tubes fitted. I've gone with Mitas - I've got them on other

bikes and they seem fine. Following that I did my rear sprocket bolt

modification. I've had the original BSA bolts work loose on more than one

Bantam, so what I do now is to tap the bolt holes out to M6 and fit longer M6

Allen pins in. It doesn't work if you use M6 bolts, the heads are too

large and will foul on the brake plate. New wheel bearings and brake shoes

were also fitted - the peg spanner I made earlier came in useful again.

Seeing as I now had the wheels, I fitted the rear one in place.

Whilst I was working on the rear wheel, I might as well fit the chain and chain

guard, which I did. The frame was still sat on its trolley, waiting for

the fork stanchions to arrive. . . .which they did. Right - next job was

putting the front end back together. This is made a lot easier if you have

a fork stanchion puller. Not the most difficult of tools to make,

providing you have an old fork top nut. I made one of these a few years

back when I had another B175 - take a look at

THIS PAGE

for details on how to make one. Having got the forks fitted, the mudguard was

next. I'm afraid the rivet counters will not be pleased because I used

stainless steel metric fasteners to hold it all together. There again, as

you will have gathered, I build bikes to be practical as opposed to factory

original. Next thing was the front wheel. This too has had new

bearings and brake shoes. Of course, seeing as I'm using non-standard

brake and clutch levers, new cables have to be made for both front brake and

clutch. I tend to make two of each - one to fit on the bike, and one to

carry as a spare.

Having done all the above, I wheeled the bike outside and started

it. Pulled the clutch in, engaged first gear and the Bantam moved under

its own power for the first time. The bike is almost finished now, but

there are still little things to be sorted out. A new exhaust system for

one. The decals for the side panels ( still waiting for 'em ) need putting

on. The little matter of insurance has to be sorted out, then an MOT

test. OK, so I know according to its age it doesn't need one, but I'd

rather my friendly MOT tester spots something I'd missed. There's a good

chance the brake cams have worn the holes in the brake plate oval - I need to

see how it behaves on the road before I go making bushes and sorting that out.

Hopefully the next thing I need to do is use the thing and run it in - staying

local for a few "shakedown runs" before attempting any serious distance.

Still, this is all part of the fun in owning a Bantam . . . or so they tell me.

The bike has now been out on a few shakedown runs. The

brakes are working fine, so I won't be re-bushing the holes just yet. The

carburettor however is a different matter. It's rather worn, rattles a bit

and is running far too rich. Time for a new Amal Premier I think.

I'm not happy with the shape of the indicators, they may look fine on a modern

bike, but they just don't suit the Bantam at all - so they will be getting

changed.

Like I said, a new Amal Premier has been fitted. It was a

bit weak on the pilot side, so I fitted the next largest pilot jet, that's made

things a lot better. One of the things I try to do with any bike I intend

using, is to find out how far it will go once the fuel tap is turned onto

reserve. I filled my one litre fuel bottle up and set off for a ride

around the Severn Valley. From going onto reserve to running out fully

took 23 miles. Funnily enough, the reserve capacity is also one litre.

This means the bike was doing 104 miles per gallon. The new decals for the

side panels arrived, so they got fitted too. Now some of the more keen

eyed folks will have noticed an earlier picture of the side panels with the

decals fitted . . . go take a closer look . . . they are fitted incorrectly and

would have been sloping down at around 30°. That'll teach me to look

before I fit next time. The only thing I'm waiting on now is the new

exhaust system.

December 2021

The new exhaust got fitted - along with a GPS speedometer ( which

you can't see during daylight hours, so that might be getting removed ) and a

LED headlight unit. I've also built a 185cc engine which is currently

sitting on the bench waiting to be fitted. I dare say I'll get around to

that sometime next year.

November 2022

Well the 185cc engine

never got fitted - although I've just bought another Bantam frame, so it might

be going in that. This year's Bantam Club national rally was at Kelsall,

where the Bantam made an appearance. I did take the Bantam down to the Ace Café, in London,

for their Bantams at the Ace day. I made it there and back without any

trouble at all. I did call in at the old BSA factory on my way back home.

November 2023

Once again the

Bantam went to the National Rally, this year being held at the Bloxham steam

fair. The Bantams at the Ace Café event in September was attended.

The Bantam made the 250 mile round trip with no bother. It seems the

Bantam will also be at the NEC in November for the Classic Motor Show. So all in

all, the Bantam has had a decent year. Oh, and I've got around to taking a

look at sorting the 185cc engine out too.